Roy Hill: Optimising Pilbara communications

Transforming processes for teams

In West Australia’s vast Pilbara region, Roy Hill is leading the way on sustainable, low-cost production of iron ore, combined with an advanced rail and port operation. Focused on supporting their people reach their full potential, Roy Hill looked to enhance their operational digital capabilities to meet the needs of their large-scale mining operation.

Advancing the way multiple, high-functioning teams collaborate and share information is a core driver for Roy Hill when it comes to transforming their mining communications. Roy Hill wished to move away from reporting processes that would only update teams daily, to a digital tool that encapsulated mining data and operational updates in near real-time.

Moving from paper to digital

The former hard copy approach to reporting resulted in a bottleneck of information between teams across multiple mining sites, making it difficult for teams to communicate on dig areas, machine maintenance schedules and blast exclusion zones across several locations.

For example, a machine’s maintenance schedule may overlap with its scheduled dig time, or a blast exclusion zone may overlap with a planned dig area and in-pit dewatering requirements may overlap dig areas. Communicating the weekly mine plan to the site operational team became a lengthy process and challenging for teams to reconcile the information.

“The demand chain viewer solution is a collaboration by a number of departments within Roy Hill with NGIS, it provides an innovative common operating picture of multiple spatial data sources and live feeds, which is very useful.”

Scott Paton, Superintendent engineering information management, Roy Hill

Automation for robust decision making

Roy Hill understood that the teams experiencing these delays needed a digital, real time reporting solution to improve the timeliness of the key information in order to drive forward with mining plans.

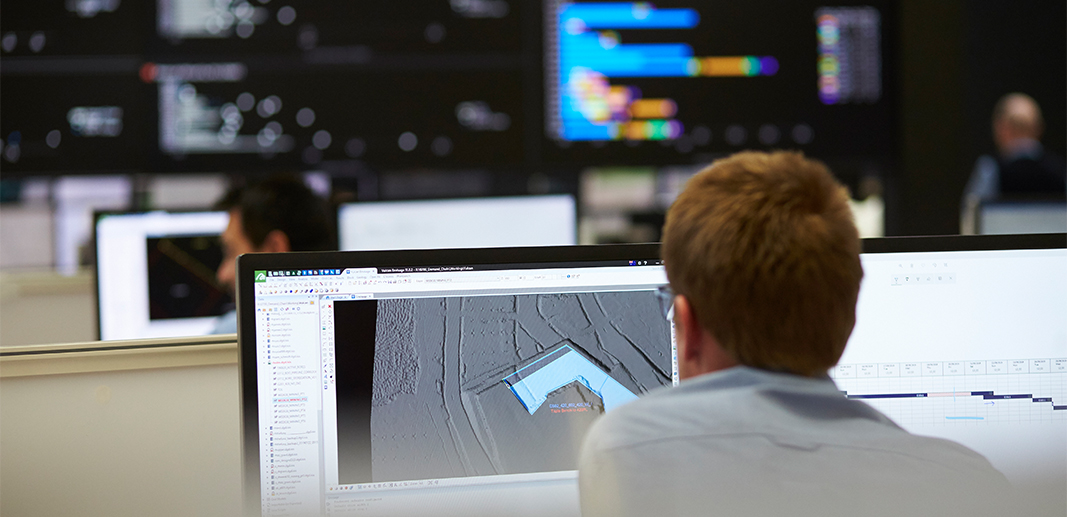

Using Esri and Geocortex technology, NGIS created the Demand Chain Viewer; a dynamic, web-based digital mapping application which allows Roy Hill to see all of the relevant operational data in one centralised location. By accessing data that’s receiving input from multiple teams across drill and blast, mine planning, dewatering, compliance and workshop, NGIS could intelligently provide a digital view of all areas across Roy Hill’s mining operation.

Automation processes have been created to keep the data updated, relevant and live – creating a real-time representation of operational movements between mining teams. The entire Integrated Demand Chain Mining Schedule (IDCMS) is now communicated through a time slider tool, allowing supervisors and engineers to more efficiently position their machines for adjacent activities and investigate longer term mining activities eight weeks out.

An intuitive approach to information visualisation

Since the demand chain viewer has been deployed, Roy Hill’s operational mining teams have integrated it as part of their decision-making processes. This has improved operational awareness for mine production engineers and supervisors to see the IDCMS schedule, machine maintenance schedules, the mine plan and other activities including; blast exclusion zones, dig and dump locations, live machine positions and updated aerial imagery from drones. It also has the ability to view historical activities through the conformance layers.

Using the map-based tool has alleviated issues created by outmoded processes, moving Roy Hill into a digitally efficient operational structure.

NGIS creates intelligent digital tools to increase operational efficiency in mining

NGIS has over 25 years of experience working with the mining and resources sector. Our solutions are tailormade to meet the specific needs of the organisations we work with. Whether it is creating an intelligent digital twin, introducing Virtual Reality capabilities to your operations, or creating a GIS tool that captures and leverages mining and exploration data to drive business decisions, productivity and efficiency improvements – we create tools that alleviate the limitations being faced by teams in large enterprise environments.

“The addition of the demand chain viewer in the mine scheduling area is one of many tools we are using in our quest to creating the digital twin environment.”

Corey Rodgers, Superintendent mine scheduling, Demand Chain, Roy Hill